ISO 4200 nyedhiyakake tabel ukuran lan bobot saben unit dawa kanggo tabung flat-end sing dilas lan mulus.

Klompok Pipa

ISO 4200 mbagi pipa baja sing dilas lan pipa baja sing mulus dadi rong klompok.

Kelompok 1: Pipa baja tujuan umum.

Standar sing umum digunakake: API 5L, ASTM A53, GB 3091, lan liya-liyane.

Kelompok 2: Pipa baja presisi.

Standar sing umum digunakake: ASTM A519, DIN 2391, lan EN 10305-1.

Makalah iki utamane mbahas tabel bobot tabung baja kanggo tujuan umum, yen sampeyan pengin ngerti tabel bobot tabung baja kanggo tabung baja presisi, monggo klik file PD standar ing ngisor iki kanggo ndeleng Page 10 Tabel 3.

Tabung baja tujuan umum lan tabung baja presisi utamane dipérang miturut beda ing presisi, materi, lan kinerja manufaktur.

Umum-tujuan tabung baja biasane nuduhake tabung baja karo pangolahan produksi relatif kurang lan syarat technical, kang utamané dipigunakaké kanggo transportasi adi-tekanan kurang umum, komponen struktural, lan sapiturute.

Tabung baja presisi, ing tangan liyane, deleng tabung baja kanthi dimensi presisi sing luwih dhuwur, kualitas permukaan sing luwih apik, lan bahan sing luwih ketat lan syarat kinerja, lan umume digunakake kanggo komponen presisi lan kinerja dhuwur ing otomotif, mesin, petrokimia, lan lapangan liyane.

Ing babagan diameter njaba lan kekandelan tembok, tabung baja presisi asring duwe syarat toleransi sing luwih ketat kanggo nyukupi kabutuhan aplikasi tartamtu.

Bagan Bobot Pipa Kelompok 1

Standar ISO 4200 kanggo tujuan umum mbagi diameter njaba tabung baja dadi telung seri

Seri 1

Seri 1: Seri sing kabeh aksesoris sing dibutuhake kanggo pambangunan sistem pipa wis standar.

| Diameter njaba (mm) | Ketebalan tembok (mm) | Massa Ujung Biasa (kg/m) |

| 10.2 | 0.5 | 0.120 |

| 10.2 | 0.6 | 0.142 |

| 10.2 | 0.8 | 0.185 |

| 10.2 | 1 | 0.227 |

| 10.2 | 1.2 | 0.266 |

| 10.2 | 1.4 | 0.304 |

| 10.2 | 1.6 | 0.339 |

| 10.2 | 1.8 | 0.373 |

| 10.2 | 2.0 | 0.404 |

| 10.2 | 2.3 | 0.448 |

| 10.2 | 2.6 | 0.487 |

| 13.5 | 0.5 | 0.160 |

| 13.5 | 0.6 | 0.191 |

| 13.5 | 0.8 | 0.251 |

| 13.5 | 1 | 0.308 |

| 13.5 | 1.2 | 0.364 |

| 13.5 | 1.4 | 0.418 |

| 13.5 | 1.6 | 0.470 |

| 13.5 | 1.8 | 0.519 |

| 13.5 | 2.0 | 0.567 |

| 13.5 | 2.3 | 0.635 |

| 13.5 | 2.6 | 0.699 |

| 13.5 | 2.9 | 0.758 |

| 13.5 | 3.2 | 0.813 |

| 13.5 | 3.6 | 0.879 |

| 17.2 | 0.5 | 0.206 |

| 17.2 | 0.6 | 0.246 |

| 17.2 | 0.8 | 0.324 |

| 17.2 | 1 | 0.400 |

| 17.2 | 1.2 | 0.474 |

| 17.2 | 1.4 | 0.546 |

| 17.2 | 1.6 | 0.616 |

| 17.2 | 1.8 | 0.684 |

| 17.2 | 2.0 | 0.75 |

| 17.2 | 2.3 | 0.845 |

| 17.2 | 2.6 | 0.936 |

| 17.2 | 2.9 | 1.02 |

| 17.2 | 3.2 | 1.10 |

| 17.2 | 3.6 | 1.21 |

| 17.2 | 4 | 1.30 |

| 17.2 | 4.5 | 1.41 |

| 21.3 | 0.5 | 0.256 |

| 21.3 | 0.6 | 0.306 |

| 21.3 | 0.8 | 0.404 |

| 21.3 | 1 | 0.501 |

| 21.3 | 1.2 | 0.595 |

| 21.3 | 1.4 | 0.687 |

| 21.3 | 1.6 | 0.777 |

| 21.3 | 1.8 | 0.866 |

| 21.3 | 2.0 | 0.952 |

| 21.3 | 2.3 | 1.08 |

| 21.3 | 2.6 | 1.20 |

| 21.3 | 2.9 | 1.32 |

| 21.3 | 3.2 | 1.43 |

| 21.3 | 3.6 | 1.57 |

| 21.3 | 4 | 1.71 |

| 21.3 | 4.5 | 1.86 |

| 21.3 | 5 | 2.01 |

| 21.3 | 5.4 | 2.12 |

| 26.9 | 0.5 | 0.326 |

| 26.9 | 0.6 | 0.389 |

| 26.9 | 0.8 | 0.515 |

| 26.9 | 1 | 0.639 |

| 26.9 | 1.2 | 0.761 |

| 26.9 | 1.4 | 0.880 |

| 26.9 | 1.6 | 0.998 |

| 26.9 | 1.8 | 1.11 |

| 26.9 | 2.0 | 1.23 |

| 26.9 | 2.3 | 1.40 |

| 26.9 | 2.6 | 1.56 |

| 26.9 | 2.9 | 1.72 |

| 26.9 | 3.2 | 1.87 |

| 26.9 | 3.6 | 2.07 |

| 26.9 | 4 | 2.26 |

| 26.9 | 4.5 | 2.49 |

| 26.9 | 5 | 2.70 |

| 26.9 | 5.4 | 2.86 |

| 26.9 | 5.6 | 2.94 |

| 26.9 | 6.3 | 3.20 |

| 26.9 | 7.1 | 3.47 |

| 26.9 | 8 | 3.73 |

| 33.7 | 0.5 | 0.409 |

| 33.7 | 0.6 | 0.490 |

| 33.7 | 0.8 | 0.649 |

| 33.7 | 1 | 0.806 |

| 33.7 | 1.2 | 0.962 |

| 33.7 | 1.4 | 1.12 |

| 33.7 | 1.6 | 1.27 |

| 33.7 | 1.8 | 1.42 |

| 33.7 | 2.0 | 1.56 |

| 33.7 | 2.3 | 1.78 |

| 33.7 | 2.6 | 1.99 |

| 33.7 | 2.9 | 2.20 |

| 33.7 | 3.2 | 2.41 |

| 33.7 | 3.6 | 2.67 |

| 33.7 | 4 | 2.93 |

| 33.7 | 4.5 | 3.24 |

| 33.7 | 5 | 3.54 |

| 33.7 | 5.4 | 3.77 |

| 33.7 | 5.6 | 3.88 |

| 33.7 | 6.3 | 4.26 |

| 33.7 | 7.1 | 4.66 |

| 33.7 | 8 | 5.07 |

| 33.7 | 8.8 | 5.40 |

| 42.4 | 0.5 | 0.517 |

| 42.4 | 0.6 | 0.619 |

| 42.4 | 0.8 | 0.821 |

| 42.4 | 1 | 0.102 |

| 42.4 | 1.2 | 0.122 |

| 42.4 | 1.4 | 1.42 |

| 42.4 | 1.6 | 1.61 |

| 42.4 | 1.8 | 1.80 |

| 42.4 | 2.0 | 1.99 |

| 42.4 | 2.3 | 2.27 |

| 42.4 | 2.6 | 2.55 |

| 42.4 | 2.9 | 2.82 |

| 42.4 | 3.2 | 3.09 |

| 42.4 | 3.6 | 3.44 |

| 42.4 | 4 | 3.79 |

| 42.4 | 4.5 | 4.21 |

| 42.4 | 5 | 4.61 |

| 42.4 | 5.4 | 4.93 |

| 42.4 | 5.6 | 5.08 |

| 42.4 | 6.3 | 5.61 |

| 42.4 | 7.1 | 6.18 |

| 42.4 | 8.0 | 6.79 |

| 42.4 | 8.8 | 7.29 |

| 42.4 | 10 | 7.99 |

| 48.3 | 0.6 | 0.706 |

| 48.3 | 0.8 | 0.937 |

| 48.3 | 1 | 1.17 |

| 48.3 | 1.2 | 1.39 |

| 48.3 | 1.4 | 1.62 |

| 48.3 | 1.6 | 1.84 |

| 48.3 | 1.8 | 2.06 |

| 48.3 | 2.0 | 2.28 |

| 48.3 | 2.3 | 2.61 |

| 48.3 | 2.6 | 2.93 |

| 48.3 | 2.9 | 3.25 |

| 48.3 | 3.2 | 3.56 |

| 48.3 | 3.6 | 3.97 |

| 48.3 | 4 | 4.37 |

| 48.3 | 4.5 | 4.86 |

| 48.3 | 5 | 5.34 |

| 48.3 | 5.4 | 5.71 |

| 48.3 | 5.6 | 5.90 |

| 48.3 | 6.3 | 6.53 |

| 48.3 | 7.1 | 7.21 |

| 48.3 | 8 | 7.95 |

| 48.3 | 8.8 | 8.57 |

| 48.3 | 10 | 9.45 |

| 48.3 | 11 | 10.1 |

| 48.3 | 12.5 | 11.0 |

| 60.3 | 0.6 | 0.883 |

| 60.3 | 0.8 | 1.17 |

| 60.3 | 1 | 1.46 |

| 60.3 | 1.2 | 1.75 |

| 60.3 | 1.4 | 2.03 |

| 60.3 | 1.6 | 2.32 |

| 60.3 | 1.8 | 2.60 |

| 60.3 | 2.0 | 2.88 |

| 60.3 | 2.3 | 3.29 |

| 60.3 | 2.6 | 3.70 |

| 60.3 | 2.9 | 4.11 |

| 60.3 | 3.2 | 4.51 |

| 60.3 | 3.6 | 5.03 |

| 60.3 | 4 | 5.55 |

| 60.3 | 4.5 | 6.19 |

| 60.3 | 5 | 6.82 |

| 60.3 | 5.4 | 7.31 |

| 60.3 | 5.6 | 7.55 |

| 60.3 | 6.3 | 8.39 |

| 60.3 | 7.1 | 9.32 |

| 60.3 | 8 | 10.3 |

| 60.3 | 8.8 | 11.2 |

| 60.3 | 10 | 12.4 |

| 60.3 | 11 | 13.4 |

| 60.3 | 12.5 | 14.7 |

| 60.3 | 14.2 | 16.1 |

| 60.3 | 16 | 17.5 |

| 76.1 | 0.8 | 1.49 |

| 76.1 | 1 | 1.85 |

| 76.1 | 1.2 | 2.22 |

| 76.1 | 1.4 | 2.58 |

| 76.1 | 1.6 | 2.94 |

| 76.1 | 1.8 | 3.30 |

| 76.1 | 2.0 | 3.65 |

| 76.1 | 2.3 | 4.19 |

| 76.1 | 2.6 | 4.71 |

| 76.1 | 2.9 | 5.24 |

| 76.1 | 3.2 | 5.75 |

| 76.1 | 3.6 | 6.44 |

| 76.1 | 4 | 7.11 |

| 76.1 | 4.5 | 7.95 |

| 76.1 | 5 | 8.77 |

| 76.1 | 5.4 | 9.42 |

| 76.1 | 5.6 | 9.74 |

| 76.1 | 6.3 | 10.8 |

| 76.1 | 7.1 | 12.1 |

| 76.1 | 8 | 13.4 |

| 76.1 | 8.8 | 14.6 |

| 76.1 | 10 | 16.3 |

| 76.1 | 11 | 17.7 |

| 76.1 | 12.5 | 19.6 |

| 76.1 | 14.2 | 21.7 |

| 76.1 | 16 | 23.7 |

| 76.1 | 17.5 | 25.3 |

| 76.1 | 20 | 27.7 |

| 88.9 | 0.8 | 1.74 |

| 88.9 | 1 | 2.17 |

| 88.9 | 1.2 | 2.60 |

| 88.9 | 1.4 | 3.02 |

| 88.9 | 1.6 | 3.44 |

| 88.9 | 1.8 | 3.87 |

| 88.9 | 2.0 | 4.29 |

| 88.9 | 2.3 | 4.91 |

| 88.9 | 2.6 | 5.53 |

| 88.9 | 2.9 | 6.15 |

| 88.9 | 3.2 | 6.76 |

| 88.9 | 3.6 | 7.57 |

| 88.9 | 4 | 8.38 |

| 88.9 | 4.5 | 9.37 |

| 88.9 | 5 | 10.3 |

| 88.9 | 5.4 | 11.1 |

| 88.9 | 5.6 | 11.5 |

| 88.9 | 6.3 | 12.8 |

| 88.9 | 7.1 | 14.3 |

| 88.9 | 8 | 16.0 |

| 88.9 | 8.8 | 17.4 |

| 88.9 | 10 | 19.5 |

| 88.9 | 11 | 21.1 |

| 88.9 | 12.5 | 23.6 |

| 88.9 | 14.2 | 26.2 |

| 88.9 | 16 | 28.8 |

| 88.9 | 17.5 | 30.8 |

| 88.9 | 20 | 34.0 |

| 88.9 | 22.2 | 36.5 |

| 88.9 | 25 | 39.4 |

| 114.3 | 1.2 | 3.35 |

| 114.3 | 1.4 | 3.90 |

| 114.3 | 1.6 | 4.45 |

| 114.3 | 1.8 | 4.99 |

| 114.3 | 2.0 | 5.54 |

| 114.3 | 2.3 | 6.35 |

| 114.3 | 2.6 | 7.16 |

| 114.3 | 2.9 | 7.97 |

| 114.3 | 3.2 | 8.77 |

| 114.3 | 3.6 | 9.83 |

| 114.3 | 4 | 10.9 |

| 114.3 | 4.5 | 12.2 |

| 114.3 | 5 | 13.5 |

| 114.3 | 5.4 | 14.5 |

| 114.3 | 5.6 | 15.0 |

| 114.3 | 6.3 | 16.8 |

| 114.3 | 7.1 | 18.8 |

| 114.3 | 8 | 21.0 |

| 114.3 | 8.8 | 22.9 |

| 114.3 | 10 | 25.7 |

| 114.3 | 11 | 28.0 |

| 114.3 | 12.5 | 31.4 |

| 114.3 | 14.2 | 35.1 |

| 114.3 | 16 | 38.8 |

| 114.3 | 17.5 | 41.8 |

| 114.3 | 20 | 46.5 |

| 114.3 | 22.2 | 50.4 |

| 114.3 | 25 | 55.1 |

| 114.3 | 28 | 59.6 |

| 114.3 | 30 | 62.4 |

| 114.3 | 32 | 64.9 |

| 139.7 | 1.6 | 5.45 |

| 139.7 | 1.8 | 6.12 |

| 139.7 | 2.0 | 6.79 |

| 139.7 | 2.3 | 7.79 |

| 139.7 | 2.6 | 8.79 |

| 139.7 | 2.9 | 9.78 |

| 139.7 | 3.2 | 10.8 |

| 139.7 | 3.6 | 12.1 |

| 139.7 | 4 | 13.4 |

| 139.7 | 4.5 | 15.0 |

| 139.7 | 5 | 16.6 |

| 139.7 | 5.4 | 17.9 |

| 139.7 | 5.6 | 18.5 |

| 139.7 | 6.3 | 20.7 |

| 139.7 | 7.1 | 23.2 |

| 139.7 | 8 | 26.0 |

| 139.7 | 8.8 | 28.4 |

| 139.7 | 10 | 32.0 |

| 139.7 | 11 | 34.9 |

| 139.7 | 12.5 | 39.2 |

| 139.7 | 14.2 | 43.9 |

| 139.7 | 16 | 48.8 |

| 139.7 | 17.5 | 52.7 |

| 139.7 | 20 | 59.0 |

| 139.7 | 22.2 | 64.3 |

| 139.7 | 25 | 70.7 |

| 139.7 | 28 | 77.1 |

| 139.7 | 30 | 81.2 |

| 139.7 | 32 | 85.0 |

| 139.7 | 36 | 92.1 |

| 139.7 | 40 | 98.4 |

| 168.3 | 1.6 | 6.58 |

| 168.3 | 1.8 | 7.39 |

| 168.3 | 2.0 | 8.20 |

| 168.3 | 2.3 | 9.42 |

| 168.3 | 2.6 | 10.6 |

| 168.3 | 2.9 | 11.8 |

| 168.3 | 3.2 | 13.0 |

| 168.3 | 3.6 | 14.6 |

| 168.3 | 4 | 16.2 |

| 168.3 | 4.5 | 18.2 |

| 168.3 | 5 | 20.1 |

| 168.3 | 5.4 | 21.7 |

| 168.3 | 5.6 | 22.5 |

| 168.3 | 6.3 | 25.2 |

| 168.3 | 7.1 | 28.2 |

| 168.3 | 8 | 31.6 |

| 168.3 | 8.8 | 34.6 |

| 168.3 | 10 | 39.0 |

| 168.3 | 11 | 42.7 |

| 168.3 | 12.5 | 48.0 |

| 168.3 | 14.2 | 54.0 |

| 168.3 | 16 | 60.1 |

| 168.3 | 17.5 | 65.1 |

| 168.3 | 20 | 73.1 |

| 168.3 | 22.2 | 80.0 |

| 168.3 | 25 | 88.3 |

| 168.3 | 28 | 96.9 |

| 168.3 | 30 | 102 |

| 168.3 | 32 | 108 |

| 168.3 | 36 | 117 |

| 168.3 | 40 | 127 |

| 168.3 | 45 | 137 |

| 168.3 | 50 | 146 |

| 219.1 | 1.8 | 9.65 |

| 219.1 | 2.0 | 10.7 |

| 219.1 | 2.3 | 12.3 |

| 219.1 | 2.6 | 13.9 |

| 219.1 | 2.9 | 15.5 |

| 219.1 | 3.2 | 17.0 |

| 219.1 | 3.6 | 19.1 |

| 219.1 | 4 | 21.2 |

| 219.1 | 4.5 | 23.8 |

| 219.1 | 5 | 26.4 |

| 219.1 | 5.4 | 28.5 |

| 219.1 | 5.6 | 29.5 |

| 219.1 | 6.3 | 33.1 |

| 219.1 | 7.1 | 37.1 |

| 219.1 | 8 | 41.6 |

| 219.1 | 8.8 | 45.6 |

| 219.1 | 10 | 51.6 |

| 219.1 | 11 | 56.5 |

| 219.1 | 12.5 | 63.7 |

| 219.1 | 14.2 | 71.8 |

| 219.1 | 16 | 80.1 |

| 219.1 | 17.5 | 87.0 |

| 219.1 | 20 | 98.2 |

| 219.1 | 22.2 | 108 |

| 219.1 | 25 | 120 |

| 219.1 | 28 | 132 |

| 219.1 | 30 | 140 |

| 219.1 | 32 | 148 |

| 219.1 | 36 | 163 |

| 219.1 | 40 | 177 |

| 219.1 | 45 | 193 |

| 219.1 | 50 | 209 |

| 219.1 | 55 | 223 |

| 219.1 | 60 | 235 |

| 219.1 | 65 | 247 |

| 273.0 | 2.0 | 13.4 |

| 273.0 | 2.3 | 15.4 |

| 273.0 | 2.6 | 17.3 |

| 273.0 | 2.9 | 19.3 |

| 273.0 | 3.2 | 21.3 |

| 273.0 | 3.6 | 23.9 |

| 273.0 | 4 | 26.5 |

| 273.0 | 4.5 | 29.8 |

| 273.0 | 5 | 33.0 |

| 273.0 | 5.4 | 35.6 |

| 273.0 | 5.6 | 36.9 |

| 273.0 | 6.3 | 41.4 |

| 273.0 | 7.1 | 46.6 |

| 273.0 | 8 | 52.3 |

| 273.0 | 8.8 | 57.3 |

| 273.0 | 10 | 64.9 |

| 273.0 | 11 | 71.1 |

| 273.0 | 12.5 | 80.3 |

| 273.0 | 14.2 | 90.6 |

| 273.0 | 16 | 101 |

| 273.0 | 17.5 | 110 |

| 273.0 | 20 | 125 |

| 273.0 | 22.2 | 137 |

| 273.0 | 25 | 153 |

| 273.0 | 28 | 169 |

| 273.0 | 30 | 180 |

| 273.0 | 32 | 190 |

| 273.0 | 36 | 210 |

| 273.0 | 40 | 230 |

| 273.0 | 45 | 253 |

| 273.0 | 50 | 275 |

| 273.0 | 55 | 296 |

| 273.0 | 60 | 315 |

| 273.0 | 65 | 333 |

| 323.9 | 2.6 | 20.6 |

| 323.9 | 2.9 | 23.0 |

| 323.9 | 3.2 | 25.3 |

| 323.9 | 3.6 | 28.4 |

| 323.9 | 4 | 31.6 |

| 323.9 | 4.5 | 35.4 |

| 323.9 | 5 | 39.3 |

| 323.9 | 5.4 | 42.4 |

| 323.9 | 5.6 | 44.0 |

| 323.9 | 6.3 | 49.3 |

| 323.9 | 7.1 | 55.5 |

| 323.9 | 8 | 62.3 |

| 323.9 | 8.8 | 68.4 |

| 323.9 | 10 | 77.4 |

| 323.9 | 11 | 84.9 |

| 323.9 | 12.5 | 96 |

| 323.9 | 14.2 | 108 |

| 323.9 | 16 | 121 |

| 323.9 | 17.5 | 132 |

| 323.9 | 20 | 150 |

| 323.9 | 22.2 | 165 |

| 323.9 | 25 | 184 |

| 323.9 | 28 | 204 |

| 323.9 | 30 | 217 |

| 323.9 | 32 | 230 |

| 323.9 | 36 | 256 |

| 323.9 | 40 | 280 |

| 323.9 | 45 | 310 |

| 323.9 | 50 | 338 |

| 323.9 | 55 | 365 |

| 323.9 | 60 | 390 |

| 323.9 | 65 | 415 |

| 355.6 | 2.6 | 22.6 |

| 355.6 | 2.9 | 25.2 |

| 355.6 | 3.2 | 27.8 |

| 355.6 | 3.6 | 31.3 |

| 355.6 | 4 | 34.7 |

| 355.6 | 4.5 | 39.0 |

| 355.6 | 5 | 43.2 |

| 355.6 | 5.4 | 46.6 |

| 355.6 | 5.6 | 48.3 |

| 355.6 | 6.3 | 54.3 |

| 355.6 | 7.1 | 61.0 |

| 355.6 | 8 | 68.6 |

| 355.6 | 8.8 | 75.3 |

| 355.6 | 10 | 85.2 |

| 355.6 | 11 | 93.5 |

| 355.6 | 12.5 | 106 |

| 355.6 | 14.2 | 120 |

| 355.6 | 16 | 134 |

| 355.6 | 17.5 | 146 |

| 355.6 | 20 | 166 |

| 355.6 | 22.2 | 183 |

| 355.6 | 25 | 204 |

| 355.6 | 28 | 226 |

| 355.6 | 30 | 241 |

| 355.6 | 32 | 255 |

| 355.6 | 36 | 284 |

| 355.6 | 40 | 311 |

| 355.6 | 45 | 345 |

| 355.6 | 50 | 377 |

| 355.6 | 55 | 408 |

| 355.6 | 60 | 437 |

| 355.6 | 65 | 466 |

| 406.4 | 2.6 | 25.9 |

| 406.4 | 2.9 | 28.9 |

| 406.4 | 3.2 | 31.8 |

| 406.4 | 3.6 | 35.8 |

| 406.4 | 4 | 39.7 |

| 406.4 | 4.5 | 44.6 |

| 406.4 | 5 | 49.5 |

| 406.4 | 5.4 | 53.4 |

| 406.4 | 5.6 | 55.4 |

| 406.4 | 6.3 | 62.2 |

| 406.4 | 7.1 | 69.9 |

| 406.4 | 8 | 78.6 |

| 406.4 | 8.8 | 86.3 |

| 406.4 | 10 | 97.8 |

| 406.4 | 11 | 107 |

| 406.4 | 12.5 | 121 |

| 406.4 | 14.2 | 137 |

| 406.4 | 16 | 154 |

| 406.4 | 17.5 | 168 |

| 406.4 | 20 | 191 |

| 406.4 | 22.2 | 210 |

| 406.4 | 25 | 235 |

| 406.4 | 28 | 261 |

| 406.4 | 30 | 278 |

| 406.4 | 32 | 295 |

| 406.4 | 36 | 329 |

| 406.4 | 40 | 361 |

| 406.4 | 45 | 401 |

| 406.4 | 50 | 439 |

| 406.4 | 55 | 477 |

| 406.4 | 60 | 513 |

| 406.4 | 65 | 547 |

| 457.0 | 3.2 | 35.8 |

| 457.0 | 3.6 | 40.3 |

| 457.0 | 4 | 44.7 |

| 457.0 | 4.5 | 50.2 |

| 457.0 | 5 | 56.7 |

| 457.0 | 5.4 | 60.1 |

| 457.0 | 5.6 | 62.3 |

| 457.0 | 6.3 | 70.0 |

| 457.0 | 7.1 | 78.8 |

| 457.0 | 8 | 88.6 |

| 457.0 | 8.8 | 97.3 |

| 457.0 | 10 | 110 |

| 457.0 | 11 | 121 |

| 457.0 | 12.5 | 137 |

| 457.0 | 14.2 | 155 |

| 457.0 | 16 | 174 |

| 457.0 | 17.5 | 190 |

| 457.0 | 20 | 216 |

Seri 2

Seri 2: Seri sing ora kabeh aksesoris standar.

Seri 3

Seri 3: Seri kanggo aplikasi khusus sing ana sawetara aksesoris standar.

Metode Petungan

M=(DT)×T×0,0246615

Myaiku massa saben unit dawa ing kilogram saben meter;

Dyaiku diameter njaba sing ditemtokake ing millimeter;

Tpunika kekandelan tartamtu ing millimeters;

Koefisien 0,0246615 nganggep kapadhetan padha karo 7,85 kg/dm.3

Asil petungan dibunderaké dadi telung angka penting kanggo nilai ing ngisor 100 lan menyang nomer wutuh sing paling cedhak kanggo nilai sing luwih gedhe.

Tabel 2- Dimensi lan massa saben unit dawa, klompok 1 lan Tabel 3-Dimensi lan massa saben unit dawa, klompok 2 ing standar ISO 4200 uga diwilang ing basis.

Ketebalan Preferred

Kanggo nyederhanakake pilihan ukuran standar kanggo pipa lan aksesoris.

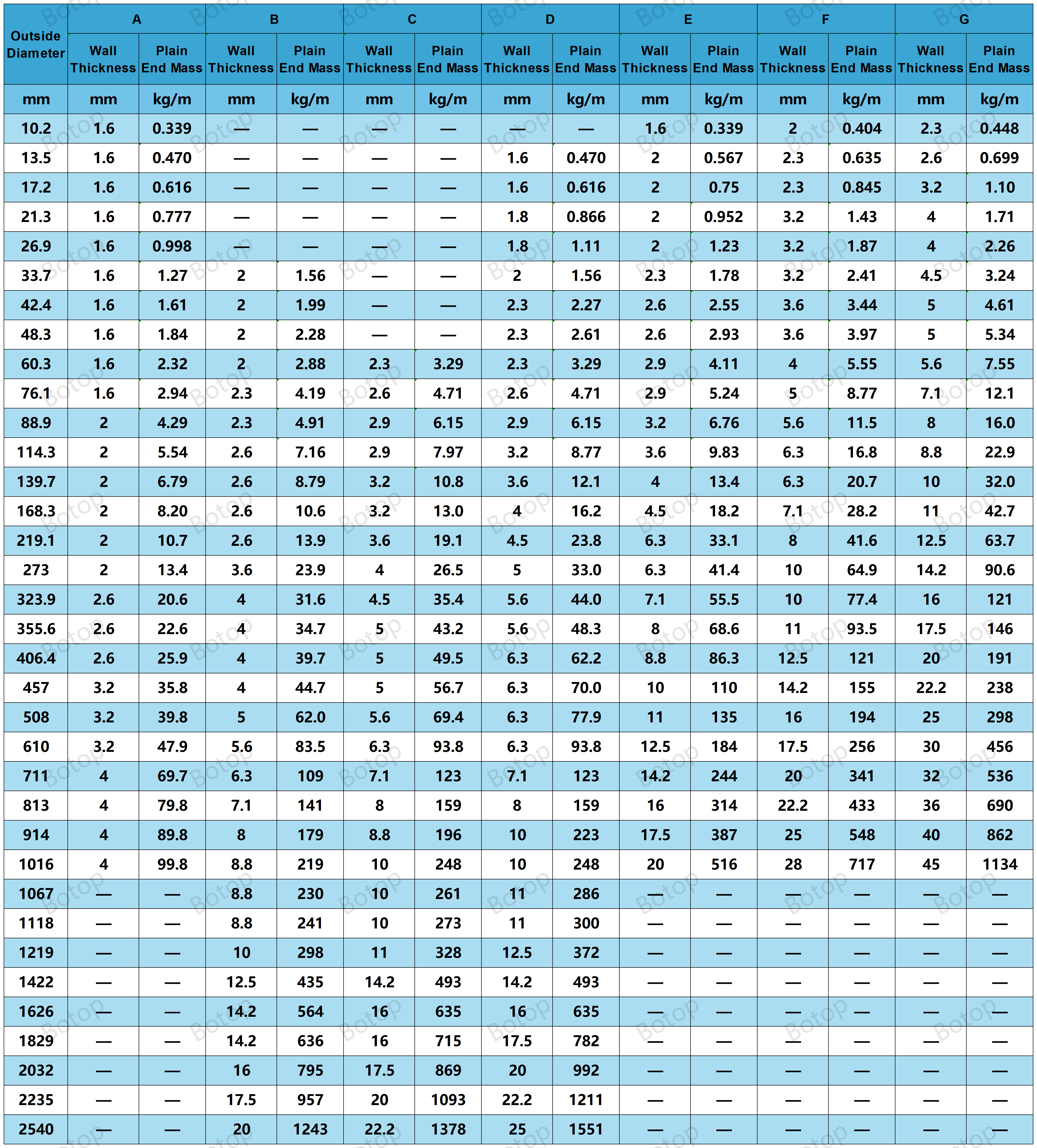

ISO 4200 uga nyedhiyakake pitung kisaran ketebalan sing disenengi kanggo diameter njaba pipa baja kanggo tujuan umum: A, B, C, D, E, F, lan G.

A, B, C, E, F, lan G: Biasane digunakake kanggo produk tubular stainless steel;

A, B, lan C: Biasane mung digunakake kanggo stainless steel, nanging ing sawetara kasus bisa digunakake kanggo jinis baja liyane;

D lan E: Preferred thicknesses kadhaptar khusus kanggo umum-tujuan flat-mburi kualitas komersial tabung baja;

D: Ora ditrapake kanggo lampiran butt-weld.

Standar sing padha

ISO 4200 Tabel 2 lan EN 10220 Tabel 1padha ing divisi saka seri pipe baja lan ing statistik bobot dimensi saka pipe baja karo kekandelan tembok ≤ 65mm.

Nanging ISO 4200 ora duwe kekandelan tembok 70mm ≤ T ≤ 100mm saka statistik bobot dimensi pipa baja.

EN 10220 nemtokake bobot dimensi pipa baja sing mulus lan dilas.Banjur ora ana divisi tabung baja dadi rong klompok: tabung baja tujuan umum lan tabung baja presisi.

Mula, sanajan loro standar kasebut asring dianggep padha utawa paling ora kompatibel ing praktik, bisa uga ana bedane ruang lingkup aplikasi lan rincian khusus, utamane ing kasus aplikasi khusus utawa syarat regional.

Tujuan Tabel Bobot

grafik bobot pipaiku kanggo nyedhiyani panuntun dhumateng kanggo ngatur pilihan saka dimensi kanggo kabeh aktivitas related kanggo standarisasi pipa baja, supaya petungan bisa siap kanggo ngindhari panggunaan kualitas beda kanggo ukuran pipa padha ing negara beda.

Kita minangka produsen lan pemasok pipa baja karbon sing dilas kanthi kualitas tinggi saka China, lan uga stokis pipa baja sing mulus, nawakake macem-macem solusi pipa baja!

tags: iso 4200, grafik bobot pipa, supplier, produsen, pabrik, stockists, perusahaan, Grosir, tuku, rega, kutipan, akeh, for sale, biaya.

Posting wektu: Mar-13-2024